Technological Development

Explore FRR possibility with high technology.

Various possibilities?are?hidden in raw materials.It?makes?the development of new technologies always face?continuous challenges. We are?working?to?find new?materials that can develop?FRP?further.Combined with countless advantages of FRP,the materials can be applied in more fields?in real life. For example, first, the SMC material which can meet the mass production?demand is?introduced into the large-scale press molding industry, even extended TMC material from YMC material (kind of SMC material developed by Yashiro). Also, Yashiro explore and develop the RIM moulding with DCPD material and autocrave moulding with carbon prepreg. Depending on Yashiro's rich experience and reality project, not just a composites company, Yashiro is creating new technology and leading the era.

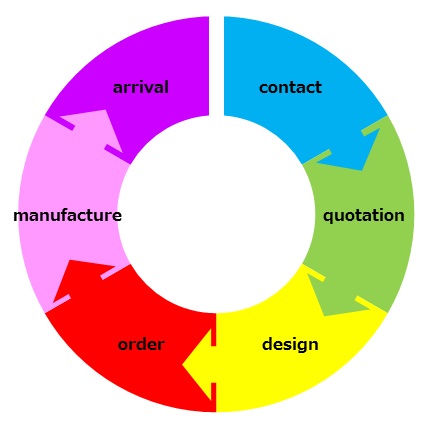

Yashiro's Design Divisio

From quotation to delivery, Yashiro is able to complete the total process independently. Satisfy with customer's QCD request and needs.

What is FRP?

FRP is Fiber Reinforced Plastics, a kind of composites material which use fiberglass to enhance plastic and increase its strength.

FRP's feature include ageing resistance, fire resistance, corrosion resistance, heat insulation, light weight and high strength.

Except glass,carbon,silicon carbideal,aramid and metal so can be treated as reinforced fiber. And resin includes unsaturated polyester resin, epoxy resin and phenolic resin.

FRP can be applied to residential assembly (bathtub, purifying tank etc.), railroad assembly (unit toilet, waste tank etc.), automobile assembly (diffuser, body etc.), healthcare assembly (CT / MRI etc.), environmental assembly (wind power generation cover etc.), from this, it can be seen that FRP already being extensive used around the world.

| GFRP | glass fiber reinforced plastics |

A strong composite material created by laminating glass fiber with unsaturated polyester resin.

|

|---|

| CFRP | carbon fiber reinforced plastics |

The composite material (prepreg etc.) that made of carbon fiber and epoxy resin become familiar beforehand was baked with autoclave device of high temperature and high pressure.

|

|---|

| DCPD | gdicyclopentadiene |

Shock resistance material formulated by RIM forming method, contains thermosetting resin.

|

|---|

| Rolling Stocks | Environmental Equipments | Medical Equipments | Residential Products | Motor Vehicles | Others | |

|---|---|---|---|---|---|---|

| hand lay‐up |  |

|

|

|

||

| pressing |  |

|

|

|

||

| RIM(Reaction Injection Molding) |  |

|

||||

| RTM(Resin Transfer Molding) |  |

|

|

|

||

| autoclaving |  |

|

Each structure's material mechanical properties

JRIS Standards

Equipment

3,000 ton molding press machine

NC router

Autoclave

RIM machine

Autograph machine

Details of Equipment

| Name | Qty | Lathe dim / width | Depth | daylight | shut height | ||

|---|---|---|---|---|---|---|---|

| Head company | Press moulding | 800t | 1 | 2,380 | 2,000 | 3,000 | 1,000 |

| Press moulding | 800t | 1 | 2,400 | 3,000 | 2,150 | 150 | |

| Press moulding | 1500t | 1 | 2,500 | 2,400 | 3,055 | 755 | |

| Press moulding | 2200t | 1 | 3,000 | 2,100 | 3,050 | 1,050 | |

| Press moulding | 2500t(L) | 1 | 3,500 | 2,800 | 3,000 | 500 | |

| Press moulding | 2500t(K) | 1 | 3,500 | 3,000 | 3,200 | 700 | |

| Press moulding | 3000t | 1 | 5,000 | 3,000 | 3,500 | 1,000 | |

| Name | qty | |

|---|---|---|

| Head company / other equipment | Bridge-type crane 10t chain block | 1 |

| high voltage room 6600V | 1 | |

| autocrave initial size φ2500×7000L | 1 | |

| NC router table 1300㎜×2000㎜ | 1 | |

| NC router table 1300㎜×2000㎜ | 1 | |

| Shimadzu autocrave | 1 | |

| Refrigerator 3400×1600H2400 | 1 | |

| Refrigerator 3500×1700H2400 | 1 | |

| Painting room area 30m2×2.4mH | 1 | |

| Cutting Ploter 3500㎜×1500㎜ | 1 | |

| RIM moulding euqipment | 2 | |

| L-RTM moulding equipment | 1 | |

| Other | - |